While not autonomous like robotic mowers, remote-controlled mowers are yet another way landscape companies are augmenting their current labor force with equipment.

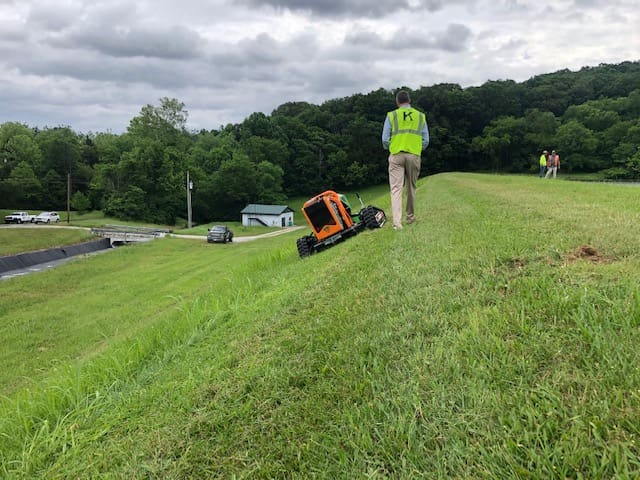

The Klausing Group, Inc., based in Lexington, Kentucky, started demoing remote-controlled mowers in 2018. Luke Tedder, LIC, business developer with Klausing Group says they tested the Ventrac and Spider units before settling on the Green Climber unit as the best fit for them.

The model Klausing Group uses has a slope rating of 60 percent. Operators can remotely control the mower up to 500 feet away. He says all three remote-control mower brands they looked at ranged between $30,000 and $40,000, depending on the included features.

Tedder says the company decided to look into remote-controlled mowers as their Louisville branch began to push into maintaining distilleries and other commercial properties with retention basins. These protected waterways have slopes that exceed the slope limitation of a standard walk-behind or riding mower.

“The inefficiency of having six to 10 people string trim those areas with the added risk of slip and fall…it was the best move we could make to both protect our employees and better serve our clients,” Tedder says.

Tedder says he had high expectations for the remote-controlled mowers.

“They’ve been exceeded since we purchased it,” he says. “The functionality as a piece of equipment, the areas that it will go and the efficiencies that it provides is just more than I could have conceived when we started down this path.”

Using the remote-control mowers, Tedder says they are able to finish the jobs in fewer hours, making it more cost-effective for customers. Tedder says their customers are elated with the introduction of the remote-controlled mowers.

“It was very well-received when they saw it on site,” he says. “Safety coordinators and plant managers have all given us some feedback that it’s both really cool, and they appreciate the added nod towards safety and keeping our guys and the property safe.”

Tedder says they haven’t encountered any issues with the slope mowers yet, but have heard that there are failings if someone exceeds the slope rating or the remote control distance.

As for the training of operating a remote-controlled mower, Tedder says it took about half a day for a long-time employee.

“The manufacturer came out with a technician and did some training with him in about three or four hours,” Tedder says. “Since then his level of confidence has only grown. He was a bit apprehensive that first day or two. It’s a very expensive, new piece of equipment so he took it really slow and he’s gradually eased into it but his comfort level and ability to operate it at a high level has come pretty quickly.”

For other companies that deal with maintaining slopes, Tedder says they should absolutely consider remote-controlled mowers. He says they are both safer and more efficient. “We took several years to make the decision we knew that it was the piece of equipment we needed, we just wanted to make sure we were investing in the right one, and that took some time, but I would say absolutely demo these pieces of equipment,” Tedder says.

He says it’s incumbent on the contractor to explain clearly to the customer the mechanical limitations of the equipment typically used in the industry and why slope mowers call for a higher-priced job.

“It was well-received with commercial clients once we sat down and said, ‘Look we’re spending uber manhours on these slopes and it’s still not the safest way to do this,’” Tedder says. “Here’s the better option. We’re willing to invest as long as that relationship goes both ways.”

This article was published in the Sept/Oct issue of the magazine.

Comments are closed.