Do you know someone who has fallen off a ladder? Did it happen on one of your jobs? Was it you? Was there an injury? Perhaps it has never happened to you and you have only heard about it while cringing through the gory details.

I believe we all recognize that ladder use is an essential part of the landscape professional’s job. However, often times a lack of understanding of ladder construction, or the failure to use the correct ladder for the assigned task, can lead to serious accidents.

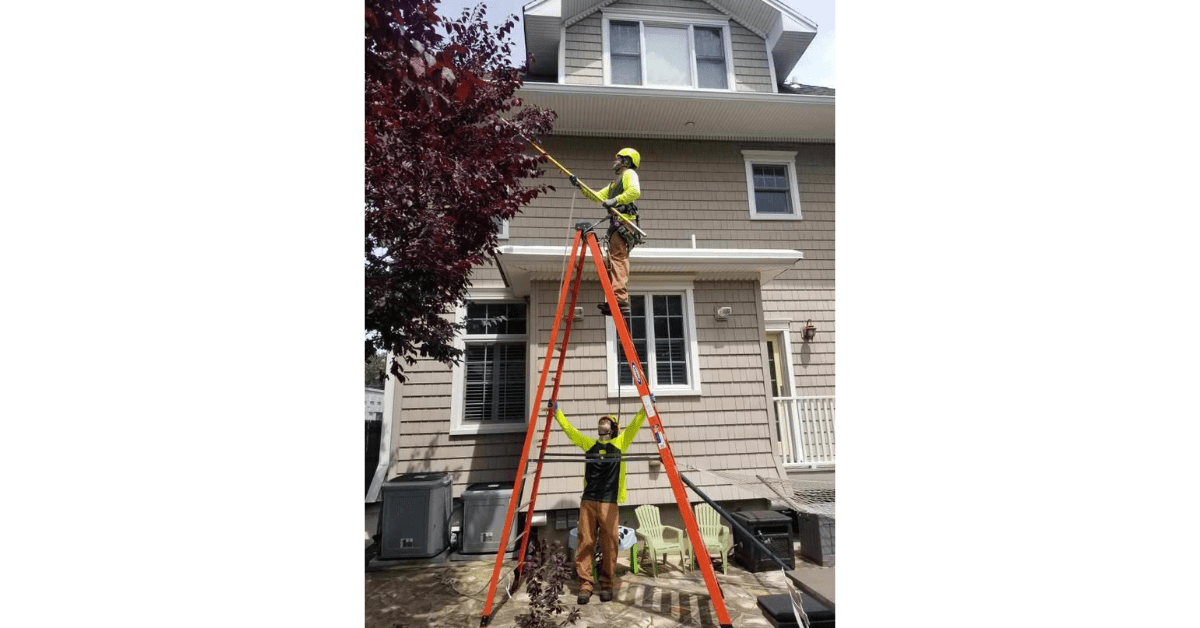

For professional use, all extension ladders should be fiberglass and have a Type 1A duty rating. It is of utmost importance that extension ladders be on firm ground, level, and footed when someone is ascending. Attempting to balance the ladder when it is not level by leaning in the opposite direction is a poor practice and can lead to a fall. Never work on an extension ladder alone.

Should a ladder fall into disrepair (worn fiberglass rails, bent rungs, or any other item listed by the manufacturer as an “out of service”), tag the ladder as out of service and discard it. Fiberglass ladders (in spite of what the internet contends) cannot be repaired and be placed back into service in the professional world.

More commonly in the landscape maintenance world, step and tripod ladders are the norm. Using the correct ladder for the assigned task is crucial.

Stepladders are generally more stable than tripod ladders because they have four legs compared to three.

Making sure the stepladder is on level ground is just as important as it is for an extension ladder.

Typically, work being performed on a ladder brings with it a number of variables: tools, positioning/repositioning, and plant parts being removed/falling.

Tripod ladders (sometimes wood, but more frequently now aluminum) allow improved access, especially in hedges and orchards to perform work.

The aluminum tripod ladder I recommend is the style that has the telescoping third leg for use on uneven surfaces.

Furthermore, purchase this ladder with a hard surface kit including skid-resistant footpads and a restraining cable for the third leg, or make sure suitable means are present to prevent skidding and stabilizing of the third leg.

Make certain to inspect the work site ahead of time and do not use an aluminum ladder within ten feet of any electrical conductor (including a house drop) on any job site.

Ladders made of fiberglass are the way to go for the professional. They are non-conductive and lightweight. They are modern and have the manufacturer’s load ratings on the side rail (1A-mentioned above is recommended-300lb load).

How many of you reading this feel that ladders are sketchy at times? If you are saying yes, you are not alone. How do we collectively stay safe on ladders? In my opinion, it comes from reviewing the things that went wrong. Here are a few examples to review at an upcoming tailgate meeting:

A worker places a tripod ladder up against a tall hedge to perform annual shearing. The third leg is in the hedge and the two other legs are on level, solid ground (concrete). The worker starts the hedge shear on the ground and carefully climbs two-thirds up the 16’ tripod to begin the work. The third leg cannot foot on a hard pad due to the tight hedge and is not stable. Halfway through the job, a combination of the unknown load on the third leg and the worker’s repositioning causes the ladder to tilt and fall.

A worker completes a hedge project with a tripod ladder. Twenty feet away a stub remains on a maple tree (approximately 15’ off the ground) from earlier pruning. Instead of going back to the truck and retrieving the stepladder, the worker decides to use the already handy tripod. The ladder is set up and as the worker climbs up to clean up the stub, the third leg sinks into some soft mulch causing the ladder and worker to fall to the ground.

If for whatever reason you or a co-worker do not feel comfortable with your ladder setup, stop and make a new plan. Ladder accidents are one of the leading causes of serious injury in our trade and they happen in an instant. Better to call a timeout than proceed with a sketchy plan while on a ladder!

This article was published in the September/October issue of the magazine. To read more stories from The Landscape Professional magazine, click here to subscribe to the digital edition.

NALP’s safety programs are produced in partnership with Rancho Mesa.